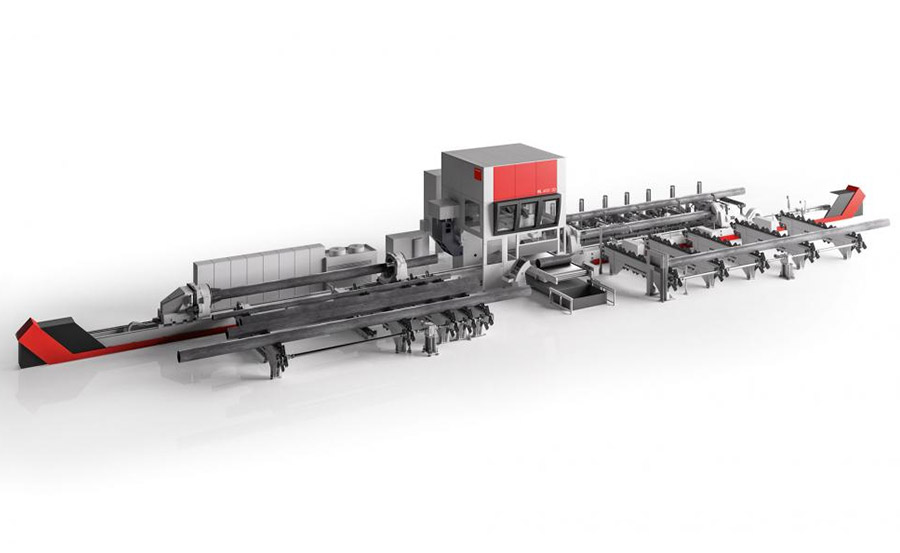

On the newest machine from Bystronic, which was purchased in 2020, we can now also process open H and I profiles with a profile diagonal of up to 406 mm which we were previously unable to process.

This technology also has a second machining head with a turret magazine for six tools, with which we are able to produce threads, calibrated holes, flowdrill etc. on a single machine and with a single material clamping. It is thus possible to achieve production cost savings by omitting operations such as cutting, drilling, milling, punching and inter-operative handling.