Materials we are able to process:

- Construction steel

- Stainless steel

- Aluminium

- Copper

- Brass

A wide range of technologies for laser cutting of flat material (CO2 lasers, Fiber lasers) allows us to process materials made of structural steel, stainless steel or aluminum, quickly and with high quality, regardless of the type and thickness of the material.

| Machine | Laser power | Max. sheet size | Max. sheet thickness, structural steel | Max. sheet thickness, stainless steel | Max. sheet thickness, aluminum | Max. sheet thickness, copper | Max. sheet thickness, brass |

|---|---|---|---|---|---|---|---|

| TruLaser 5030 CO2 | 6000 W | 3000x1500 mm | 25 mm | 25 mm | 15 mm | - | - |

| TruLaser 5030 Fiber | 3000 W | 3000x1500 mm | 20 mm | 15 mm | 15 mm | 6 mm | 6 mm |

| Adige SYS LT9 | 3000 W | 3000x1500 mm | 5 mm | 6 mm | 4 mm | 3 mm | 4 mm |

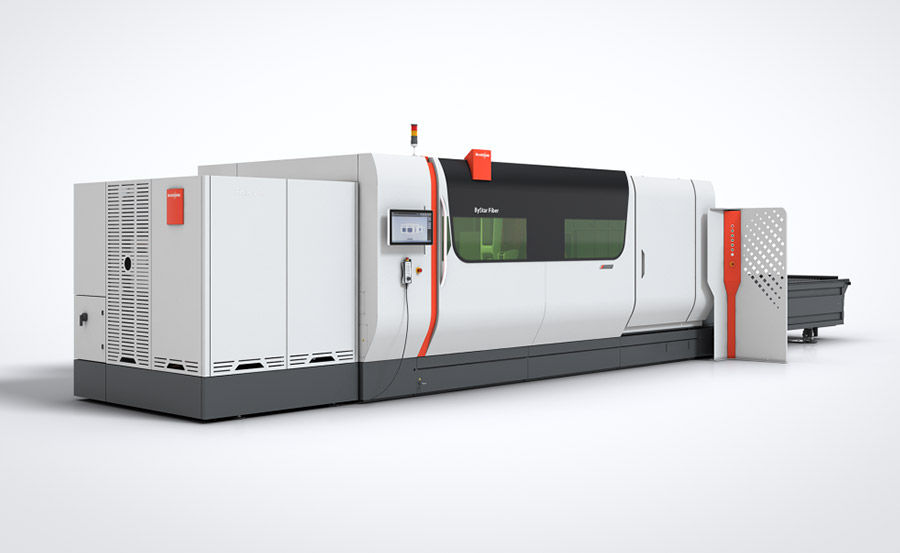

| Bystronic ByStar Fiber 6000 | 6000 W | 3000x1500 mm | 25 mm | 30 mm | 30 mm | 12 mm | 12 mm |

We have the possibility of laser cutting, where air is used as an assist gas. This technology is particularly interesting from an economic point of view in the processing of thin sheets, as it is more cost-effective and time-saving than the use of nitrogen and oxygen as the assist gas.

Using the CoolLine function, we can also create small contours in thick structural steel (thickness 15 and more mm). The structural steel becomes very hot during laser cutting and as a result it can melt uncontrollably. Using a special nozzle, the material around the laser beam is cooled by water mist. The use of CoolLine technology enables new geometries and significantly increases process reliability.

Sazovice 191, 763 01