Materials we are able to process:

- Construction steel

- Stainless steel

- Aluminium

The punching technology is especially suitable for parts with multiple holes and simple contour shapes. Thanks to the combined machine (laser - punch), however, we are able to produce parts with more complex shapes. In addition to punching, these machines offer the possibility of forming sheet metal parts or threading.

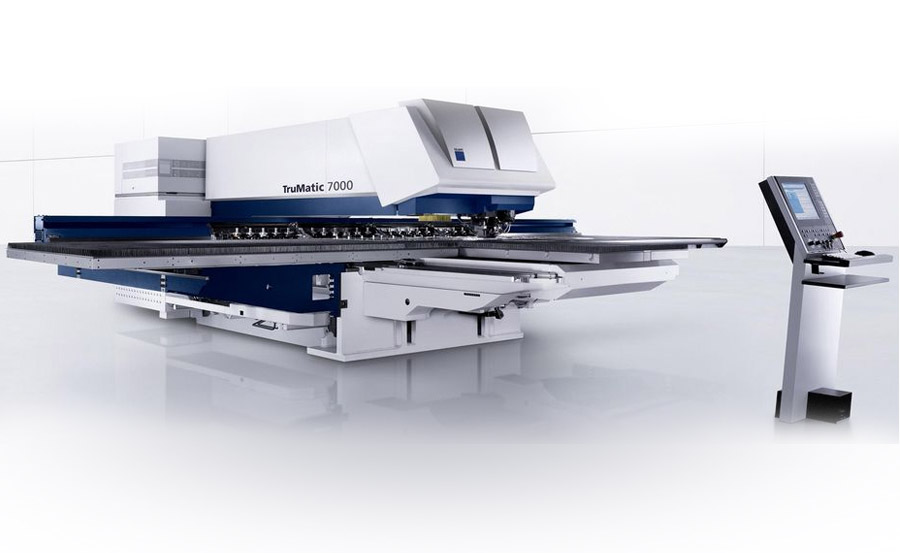

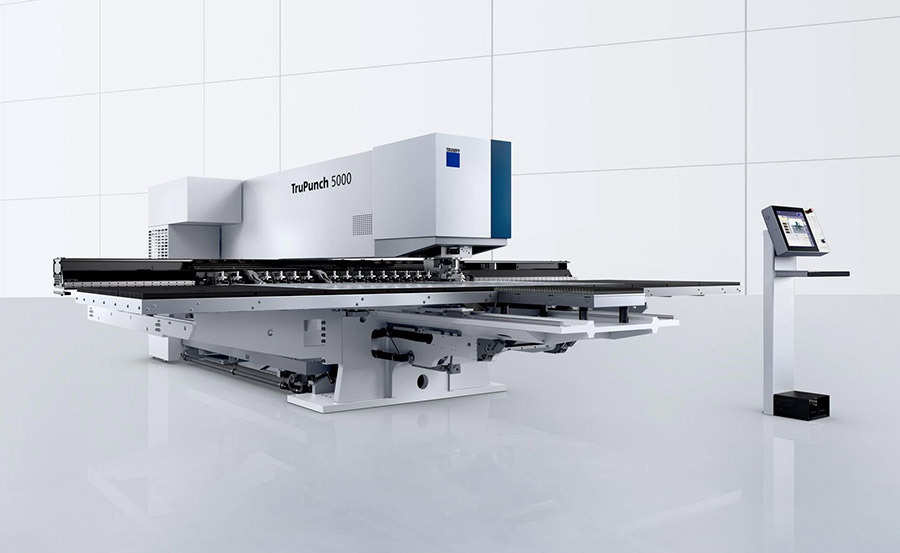

| Machine | Laser power | Max. sheet size | Max. dimensional and geometric accuracy | Max. sheet thickness, structural steel | Max. sheet thickness, stainless steel | Max. sheet thickness, aluminum |

|---|---|---|---|---|---|---|

| TruMatic 7000 | 3200 W | 3000x1500 mm | 0,2 mm | 4 mm | 2 mm | 3 mm |

| TruPunch 5000 | - | 3000x1500 mm | 0,2 mm | 3 mm | 1,5 mm | 3 mm |

| TruMatic 3000R | - | 2500x1250 mm | 0,2 mm | 2,5 mm | 1,5 mm | 3 mm |

We have tools for double-sided countersinking, forming threads of sizes M3-M8, making shaped recesses (eg for the conical head of the screw), production of ventilation holes for machine covers, making short bends, signing (reinforcing larger areas with grooving recess), marking, etc.

Thanks to the flexible bending tool, we are able to produce various bending lengths and heights up to an angle of 90 ° directly on the punching machine. Bending lengths from 5 to 90 mm and heights from 10 to 25 mm can be produced. This tool is able to create bends with almost no bruises.

Sazovice 191, 763 01