TECHNICAL PARAMETERS

- MIG/MAG output 480 A

- PLAZMA TIG output 480 A

- MicroMIG output 300 A

- We’re welding: structural steel, stainless steel, aluminum

- Maximum weldment size: 2500x1600x1000 mm length

- Maximum weldment weight: 250 kg

We offer a wide range of welding capabilities in the form of three industrial robotic welding workplaces, one workplace with a collaborative robot and two laser welding workplaces on the TRUMPF and PRIMA POWER LASERDYNE machines.

These welding capacities are suitable for medium and large batches. For small or prototype series we use manual welding workstation with jig tables.

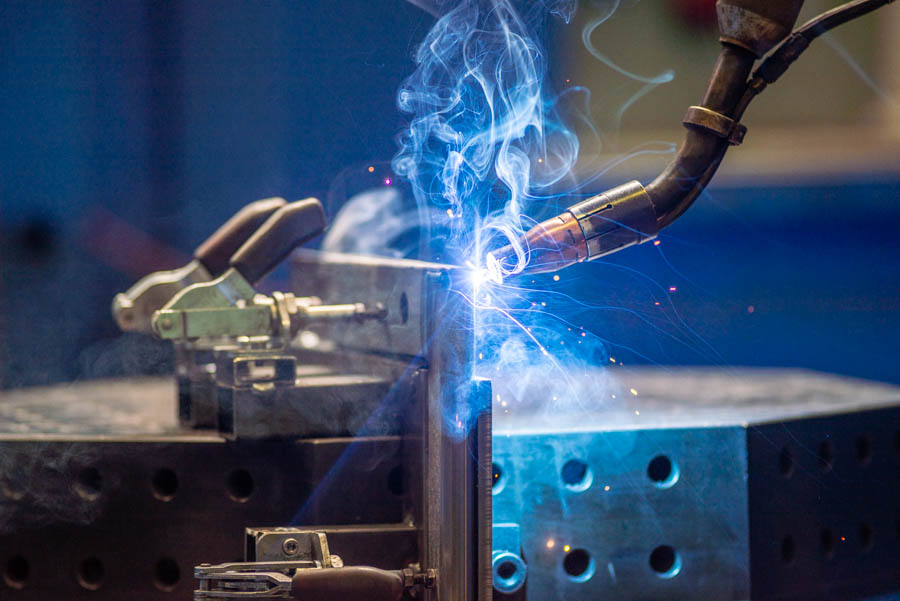

We offer the capacity of three robotic workplaces which are equipped with high quality welding robots.

We offer the MIG-MAG, PLASMA, TIG and MICRO MIG welding methods.

Welding using the MIG/MAG method is understood as welding with a fusion electrode in a protective atmosphere which also includes several arc welding methods using different kinds of additive materials and protective gases.

PLAZMA TIG means welding with a wolfram electrode in a protective atmosphere. The melting of the joined parts is caused by an electric arc which burns in between the electrode and the welded parts. Plasma welding has a wide range of applications for demanding joints up to 8 mm thick.

MicroMIG is a mechanical separation of droplets without pulses. An active arc is being repeatedly formed between the moving wire and the workpiece. The high voltage initiates melting of the wire electrode - a droplet flows into the welding bath. This method is especially suitable for welding thin materials.

It is a workstation designed for direct contact between the operator and the robot. This, in some cases, results in shorter set-up times. The collaborative robot is equipped with MIG/MAG welding technology and is especially suitable for less and medium demanding assemblies.

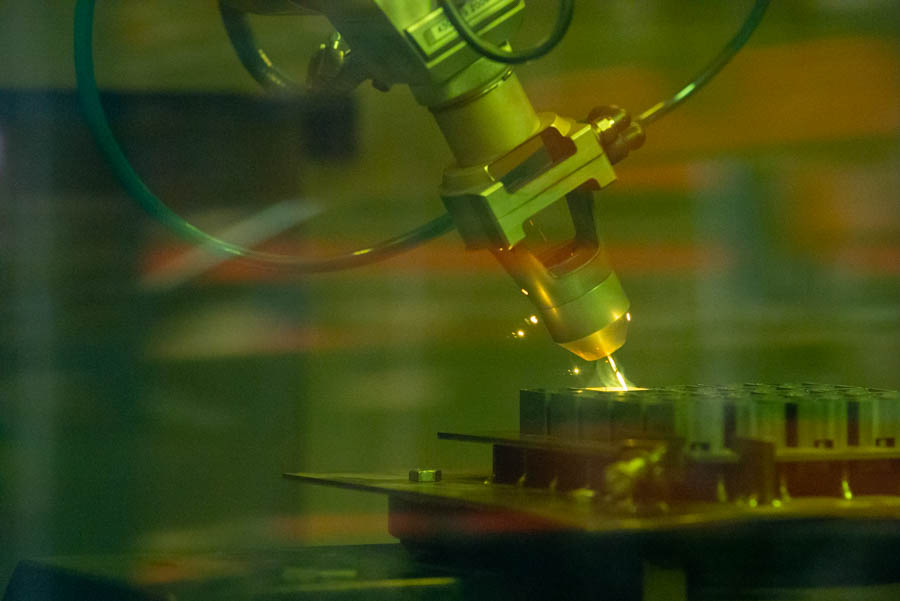

This welding technology is made possible by the laser cutting machines from TRUMPF and PRIMA POWER LASERDYNE.

Laser welding is one of the most modern technologies, thanks to which we can weld both thin sheets as well as massive structures. In our case the welding happens without additional material. This method is also suitable for a weld which is not modified any further and is on the viewing sides.

Sazovice 191, 763 01